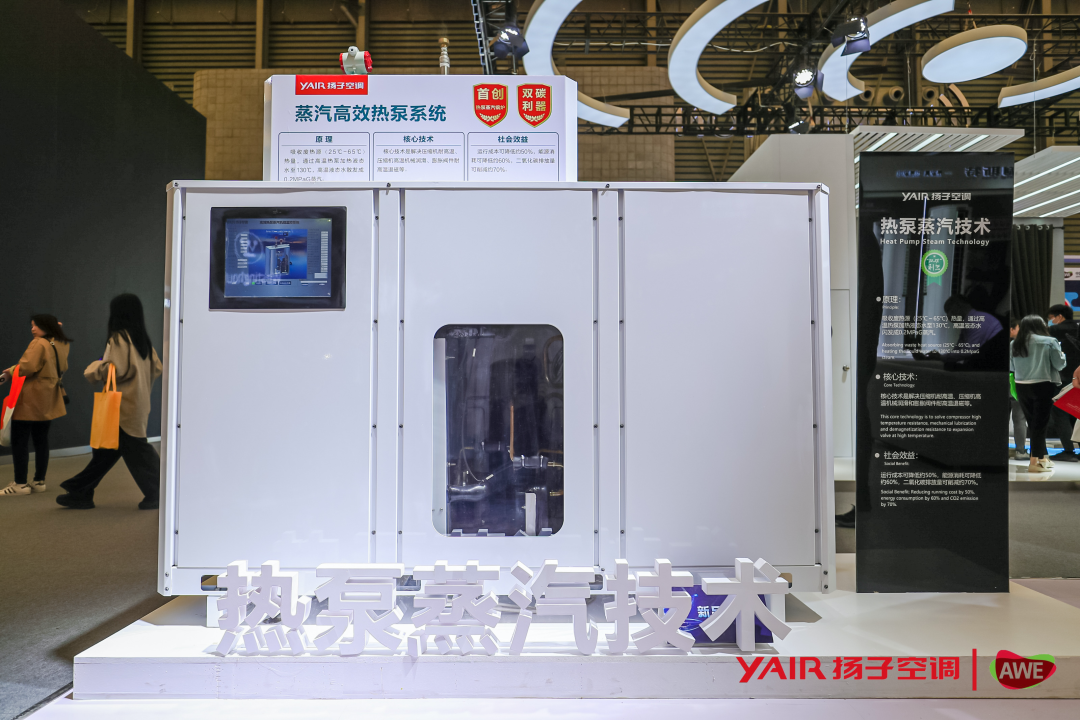

According to Liang Tao, deputy director and vice president of Yangzi Air Conditioning Technology Center: This "high efficiency heat pump steam unit" uses the two-stage scroll compression technology is the industry's first application in the field of heat pump steam, the two-stage scroll compression technology is currently the industry's leading frontier technology, which refers to the continuous compression of air in different chambers of the compressor, so that the compression ratio is multiplied, you can obtain more efficient heating capacity.

"High efficiency heat pump steam unit" can quickly convert low temperature and normal temperature tap water to 130℃ high temperature liquid water, and flash into 0.2MPaG high temperature steam, widely used in catering food, textile and clothing, chemical printing and dyeing industries, most of the above industries use traditional coal and oil boilers to make steam. Or the high-temperature steam purchased from a nearby thermal power plant for power generation, which is used after cooling and pressure reduction, has high cost, heavy pollution and large temperature and pressure fluctuations, which is not conducive to stable production. Yangzi "High efficiency heat pump steam unit" can completely replace the traditional steam supply method of the above industry, compared with coal-fired (oil) boilers, energy consumption can be reduced by 60%, and carbon dioxide emissions are reduced by about 70%.

In addition, the steam unit can also integrate waste heat recovery technology, can make full use of waste heat in industrial wastewater and waste gas, and can meet the needs of the initial stage of heating (0-100 ° C) of coal-fired thermal power plants, and the overall operating cost can be reduced by about 50%, saving a lot of energy costs for enterprises and significantly improving operational efficiency.